3D Printing Parts at Fuel Exhausts

Posted in Fuel News

Boys And Their Toys

The engineering workshop here at Fuel Exhausts is Damian’s kingdom.

Alongside designing and manufacturing the finest British-made aftermarket motorcycle exhausts, Damian also loves toys.

And one of the best bits about Damian’s job is that it gives him the perfect excuse to buy more toys!

That’s why the Fuel workshop is equipped with the finest tools alongside amazing machines like the tube expander and the mandrel pipe bender, because this is the kind of kit that produces beautifully engineered exhausts which will last a lifetime.

But the latest new toy to arrive at Fuel HQ isn’t actually in the workshop, it’s in the design studio. And it’s a phenomenal piece of kit – a Elegoo Neptune 4 Max 3D Printer.

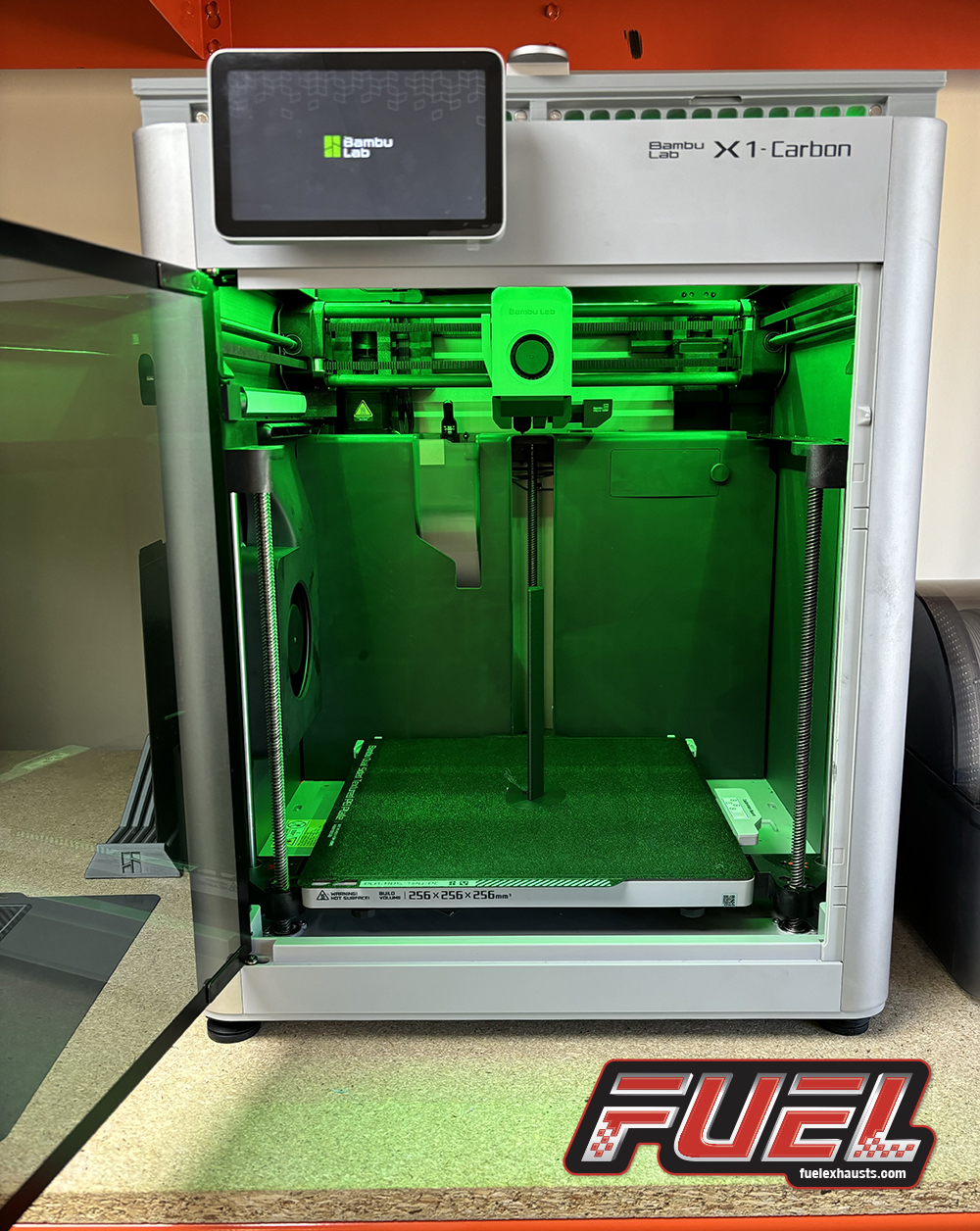

And guess what? We’ve already got two other 3D printers, but this new one has a much larger printing area. Damian started his 3D printer collection in September 2021 with a Prusa i3 MK3S, then added a neat Bambu Lab X1-Carbon in November 2022.

We use 3D printers for creating prototypes of two key components of our aftermarket motorcycle exhausts, the hangers and the end tips, as well as a host of other items which support the production process.

The hangers are unique to particular makes and models of bike. They have to fit perfectly, and of course they also have to look great. Working with CAD designs is all well and good, but a full sized 3D printed model of the component is so much better. It means you can fit a real exhaust to a real bike, you can be 100% certain that the design is spot on, and you can see how it looks from every possible angle. It’s the difference between thinking you’ve got it right, and knowing you’ve got it right.

The same applies to the end tips. Just look at the carbon fibre tips on our Diablo and Stealth exhaust ranges. They look absolutely right, and there’s a reason for that. It’s because we were able to make literally hundreds of different design variations, economically and entirely in-house, enabling us to see, touch, and feel the real thing, fitted to a real can on a real bike. So again, when we chose the final design we really knew it was right.

And then Damian started to play

We all do it, don’t we? Sit down with a brew for five minutes, and all of a sudden your mind starts to wander. What if I did this? I wonder if that might work?

When you’ve got a 3D printer you can make literally anything, right?

You could design a few motorcycling accessories, right? You could just leave the printer churning them out overnight, and they’d be sitting there waiting when you got to work in the morning. Wouldn’t even take up any ‘work’ time. Hmmm…

So, here we have the first of Damian’s little side projects. We’ve got a set of drinks coasters, and a neat little rack to keep them in.

And the next day we’ve got another set. Now we’ve got heaps of coasters including KTM, Kawasaki, Suzuki, Yamaha, Honda and a rather nice black and white Tiger set. Damian is working on these daily so we will be able to offer more designs soon.

Do you want some? Drop us a line if you’d like one, they’re just £27.99 for a set of 4 complete with rack.

Hey – let’s have a competition!

What else can we make? What would you like? Give us your ideas for a motorcycling accessory, a gadget, or an item of merchandise. And here’s the deal – if yours is the best idea, then we’ll make it and send you one. For free.

Send your ideas to [email protected] and tell us what you want us to make.